Everything About Membrane Layer Switch: Understanding Its Layout and Capability

When you think regarding the control interfaces in contemporary devices, membrane layer switches typically come to mind. Let's explore what collections membrane layer switches apart from various other control systems.

What Are Membrane Buttons?

Membrane switches can also be tailored relating to shape, dimension, and graphics, permitting suppliers to create distinct interfaces customized to details products. On the whole, membrane layer switches play a considerable duty in boosting user experience across a broad selection of applications.

How Membrane Switches Over Work

When you press a secret on a membrane layer switch, it activates an uncomplicated yet effective mechanism. The leading layer, often made of flexible material, presses down onto a conductive layer beneath it. This activity bridges the gap in between conductive traces, completing an electrical circuit. As quickly as the circuit shuts, it sends out a signal to the device's controller, which analyzes your input.

You'll notice that the tactile comments differs based on the switch layout, using either a soft click or an extra pronounced action. When you launch the trick, the membrane go back to its original placement, resuming the circuit and stopping the signal. This process takes place practically instantaneously, guaranteeing a receptive customer experience.

Membrane buttons are popular as a result of their resilience and resistance to dirt and wetness, making them suitable for numerous applications, from household appliances to clinical gadgets. Comprehending this operation assists you appreciate their extensive usage.

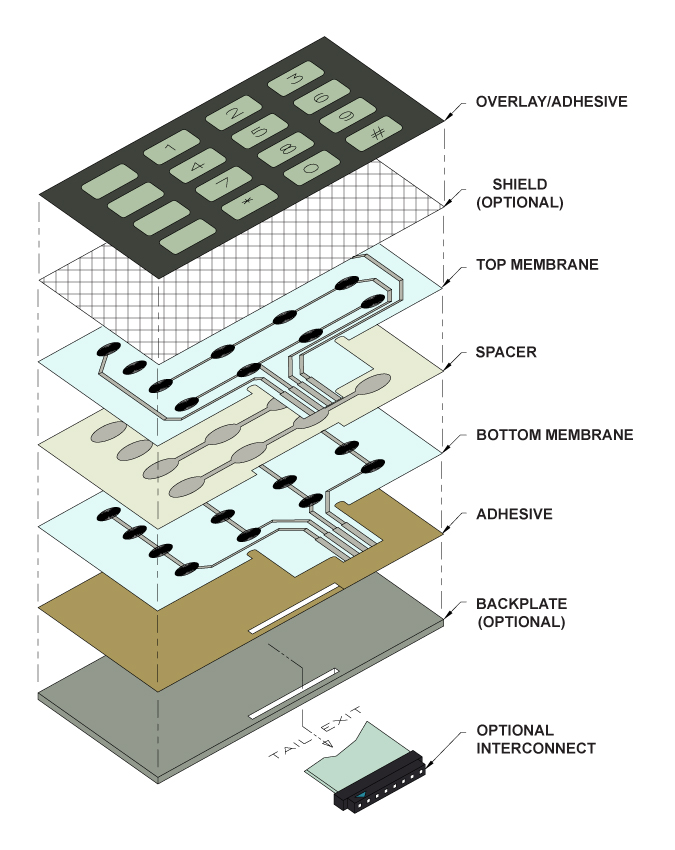

Secret Parts of Membrane Buttons

Comprehending the essential elements of membrane layer buttons is basic for understanding their functionality and design. At the core, you'll discover the graphic overlay, which provides the aesthetic user interface for customers. Beneath that, there's a spacer layer that separates the circuit layers, making certain that they do not make get in touch with till pushed. The circuit layer is where the magic occurs; it is composed of conductive traces that complete the circuit when you press the button. An additional necessary element is the sticky backing, permitting the button to abide by surfaces firmly. Finally, the safety layer shields against environmental factors and wear, extending the switch's lifespan. Each component plays a considerable role in guaranteeing reliable efficiency and user interaction. By understanding these parts, you'll get insight right into exactly how membrane switches over run and their value in various applications.

Materials Made Use Of in Membrane Layer Switch Over Design

The efficiency and longevity of membrane switches greatly rely on the products made use of in their layout. You commonly run into polyester and polycarbonate as key substrates because of their outstanding strength and flexibility. These materials withstand scratches and chemicals, making them ideal for demanding atmospheres.

The conductive layers usually utilize silver or carbon, picked for their integrity and conductivity. membrane switch manufacturer. Silver provides exceptional performance, while carbon is a cost-efficient choice. For the overlay, you may take into consideration a matte or glossy surface, depending upon your aesthetic requirements and individual experience

Make specific to select adhesives that stand up to environmental variables like temperature level and moisture. Picking the best materials will guarantee your membrane layer button stands the examination of time.

Design Factors To Consider for Membrane Layer Buttons

While creating membrane layer buttons, it's crucial to take right into account numerous variables that influence their performance and customer experience. Begin by concentrating on the design and switch dimension; make particular they're instinctive and easy to browse. Consider the tactile comments you intend to supply-- will individuals need an obvious click or a softer touch? Additionally, think of the materials you'll utilize, as they'll affect longevity and appearances.

Confirm your design accommodates environmental factors, like dampness or temperature level variants, which can influence efficiency. By carefully thinking about these components, you'll produce a membrane button that enhances usability and fulfillment.

Applications of Membrane Layer Buttons

Membrane layer buttons are functional elements discovered in numerous applications, from industrial devices to customer electronic devices. You'll see their effect in devices that require sturdy interfaces and in gadgets that gain from streamlined styles. Comprehending these applications helps you value the functionality and practicality of membrane layer switches in day-to-day innovation.

Industrial Tools Use

When you're looking to enhance the functionality of industrial devices, membrane layer buttons provide a reputable remedy that combines resilience with easy to use layout. These buttons are perfect for harsh atmospheres, supplying resistance to dirt, dampness, and chemicals. Welcome membrane switches to enhance your procedures and enhance general efficiency.

Customer Electronic Devices Integration

In the domain of customer electronic devices, membrane layer switches play an important function in improving customer interaction and device capability. Membrane layer buttons additionally ensure toughness and resistance to dust and wetness, expanding the lifespan of your electronics. By selecting membrane switches, you boost not just the performance yet also the design of your gadgets, making everyday interactions smooth and delightful.

Advantages and Disadvantages of Membrane Buttons

While membrane buttons supply a series of advantages, they likewise come with some downsides that you must think about. One substantial advantage is their compact layout, making them perfect for space-constrained applications. They're also cost-effective, giving a durable remedy with a reduced production expense. Additionally, their smooth surface is easy to clean, boosting hygiene in atmospheres like hospitals.

However, there are downsides. Membrane layer buttons can have a shorter life expectancy compared to mechanical buttons, particularly under hefty usage. They can also be much less tactile, which may affect customer comments during operation. Furthermore, if harmed, fixing navigate here them can be look at this site difficult and typically requires complete replacement. Eventually, their level of sensitivity to extreme temperatures and environmental problems may restrict their effectiveness in specific settings. Stabilizing these pros and cons will certainly help you establish if membrane switches are the best fit for your job.

Regularly Asked Questions

The Length Of Time Do Membrane Changes Typically Last?

Membrane layer changes commonly last in between 5 to one decade, relying on usage and ecological problems. You'll intend to review factors like wear, direct exposure to dampness, and temperature level changes to gauge their durability successfully.

Can Membrane Layer Switches Be Custom-made for Certain Layouts?

Yes, you can tailor membrane switches to fit details designs (membrane switch manufacturer). You'll have the flexibility to select shades, forms, and designs that match your task's requirements, guaranteeing they blend perfectly with your overall aesthetic

What Is the Expense Array for Membrane Change Production?

The cost range for membrane button production normally falls in between $1 and $10 per device, depending on elements like design intricacy, quantity, and products. You can obtain quotes from manufacturers to discover the most effective alternative.

Are Membrane Layer Switches Water Resistant or Immune?

Membrane buttons can be designed to be waterproof or resistant, depending upon products made use of and building and construction methods. If you need them for wet environments, ensure you define those needs throughout the layout procedure.

Just How Do Membrane Switches Compare to Traditional Switches?

Membrane layer buttons are typically thinner and much more flexible than conventional switches, offering a sleek design. They're typically simpler to clean and incorporate, however might not supply the tactile responses you're made use of to with mechanical alternatives.

Final thought